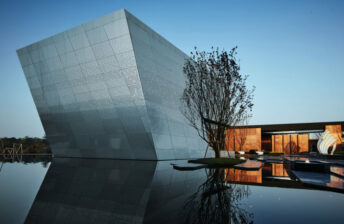

3A Composites have used their vast experience with aluminium façade panels to develop Alucolux Solid Aluminum. This enhances our extensive range of high performance cladding solutions. Alucolux is a 3mm solid, coil coated aluminium sheet material for exterior cladding and interior linings. Alucolux is available in most of the same colours found in the Alucobond Plus range and is also available in embossed surfaces to liven up the Wood Look and Stone Look ranges.

Developed from the optimum marine grade aluminium, Alucolux® is the perfect combination of temper and hardness. Architectural cladding applications require the correct combination of these properties to perform when exposed to wind loads and pressure. Alucolux® provides a non-combustible cladding solution for compliance and safety with no complications. Deemed non-combustible and certified to AS1530.1.

Alucolux provides solutions for architects, designers, developers, builders and construction companies looking for a premium solid aluminium façade panel they can safely specify for commercial, educational, aged care and residential projects without compromising design. This compliments our range of Alucobond Plus, Alucobond A2 and Alucore A2 resulting in superior performance across and price range.

Benefits

- 100% Non-combustible to AS1530.1, BS8414 to BR135 full scale wall assembly test

- Custom sizes, colours and finishes

- Guaranteed Premium PVDF finish

- High quality marine grade aluminium specifically developed for architectural facades

- Easy to fabricate

PVDF RESIN finish:

ALUCOLUX® solid aluminium panel is available as an in-house pre-finished panel with a fluorocarbon PVDF coating applied through a reverse roller coating process. The coating is backed up through a valid and approved license from the paint supplier to the manufacturer. The standard three coat system consists of a chromate conversation coating, an inhibitive primer, with a colour and top coat containing not less than 70% Polyvinylidene Fluoride (PVDF) resin by weight, and a total dry film thickness between 28-45 microns. This system provides a long lasting premium finish. Its also allows for an vast range on innovative finishes.

Specifications:

| Technical Properties | ALUCOLUX® |

| Alloy | 3003 |

| Temper | H24 |

| Standard Thickness | 3mm (Tolerance +/- 0.15mm) |

| Standard Widths | 1250mm,1500mm |

| Standard Length | </= 4000mm (Tolerance +/-6mm) |

| Panel Weight | 8.1 Kg/m2 |

| Tensile strength | 165-185 Mpa |

| Coating system | PVDF (70-30) |

| Coating thickness | 28-45 microns |

SCOPE OF USE

- High Rise Buildings

- Industrial Buildings

- Public Buildings

- Tunnels, Stations, Subway Stations

- Airports

- Hotels, Hospitals, Shopping Malls

- Stadiums, Event Halls

BENEFITS

- 100% Non-combustible to AS1530.1

- Custom sizes, colours and finishes

- Guaranteed Premium PVDF finish

- High quality marine grade aluminium specifically developed for architectural facades.

- Easy to fabricate

KEY FEATURES

- 3mm solid non-combustible aluminium

- Coil coated for colour consistency

- Surfaces can be textured

- 1500mm wide sheet size up to 6000mm long can be provided

Ordering and Sheet Size:

In-stock colours are available in 3500mm x 1500mm sheets with a minimum order of 500m². Any other colours will be indented, lead time and minimum order charges may apply.