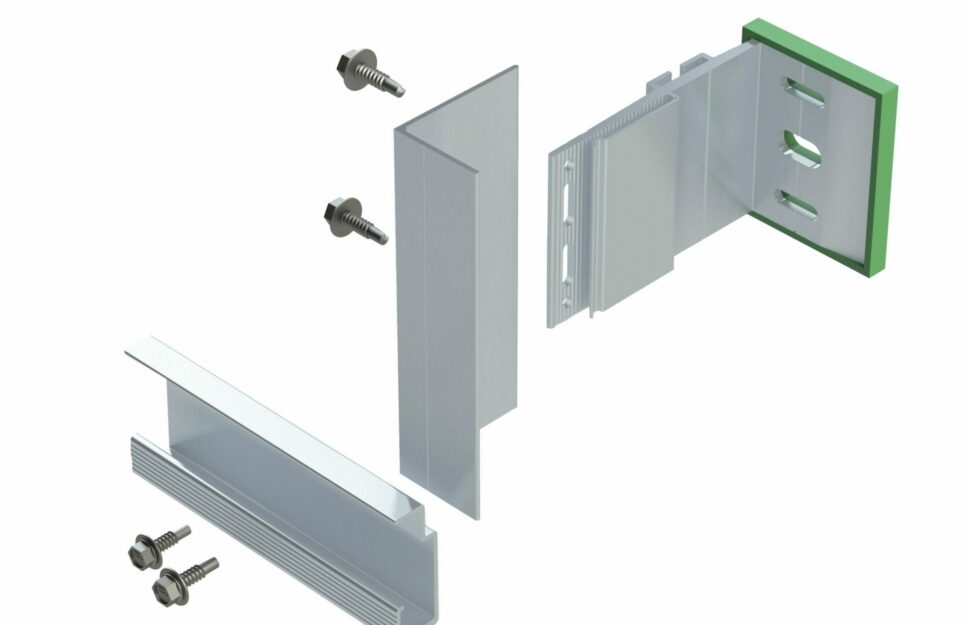

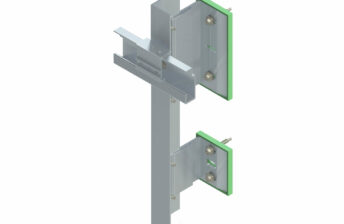

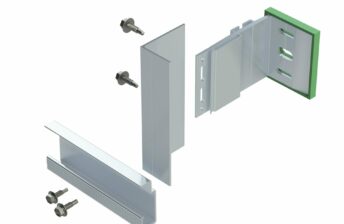

Concealed Fixing System – NV3 elements – high-pressure laminate (HPL), ceramic, thin stone including fibre cement. Horizontal NVELOPE channel profiles are fixed to the vertical profiles. Rainscreen panels are hung from and secured with hangers.

Features

- NV3 is the NVELOPE subframe system for concealed fix/mechanically secret fixed applications.

- Secured using hangers and TUF rivets to enable a concealed fix.

- Horizontal NVELOPE profiles are fixed to the vertical profiles. Rainscreen panels are supported by and secured to the horizontal profiles with hangers and adjustable hangers.

- NVELOPE ‘L’ profiles are fixed using NVELOPE support brackets, fixed through a series of fixed and sliding points.

- NVELOPE fixed point brackets absorb both vertical dead loads.

- NVELOPE bracket spacing is determined by cladding options such as the dimensions and weight of the façade cladding, local wind loads.

- NVELOPE flexible point brackets absorb wind loading and allow for expansion and contraction.

Material

The selection of materials to use in the construction of a subframe system within a rainscreen façade is of paramount importance. Material choice can also affect the thermal performance of the overall rainscreen in addition to engineering assurance.

Aluminium

- Aluminium subframe systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Parts 1-4

- Aluminum is the second most widely used metal after iron and as such has a robust and well defined UK and international supply chain

- Its low weight and high strength ratio and simplicity of fabrication either on site or within a manufacturing setting ensures it is an ideal material with which to create high performance rainscreen subframe systems for cladding applications.

- Aluminium is inherently corrosion resistant however this can be complemented and further improved by additional treatment including anodization whilst still maintaining a Euroclass A1 fire rating.

- NVELOPE systems only use the superior 6005 T6 alloy which provides superior strength and performance over and above other commonly used aluminum.

Stainless Steel

- Stainless steel subframe bracket systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 3 – Table 5.1

- NVELOPE stainless steel brackets are only manufactured from a superior 316 grade of alloy to provide an outstanding level of resistance to localised corrosion such as maritime and polluted areas.